Introduction

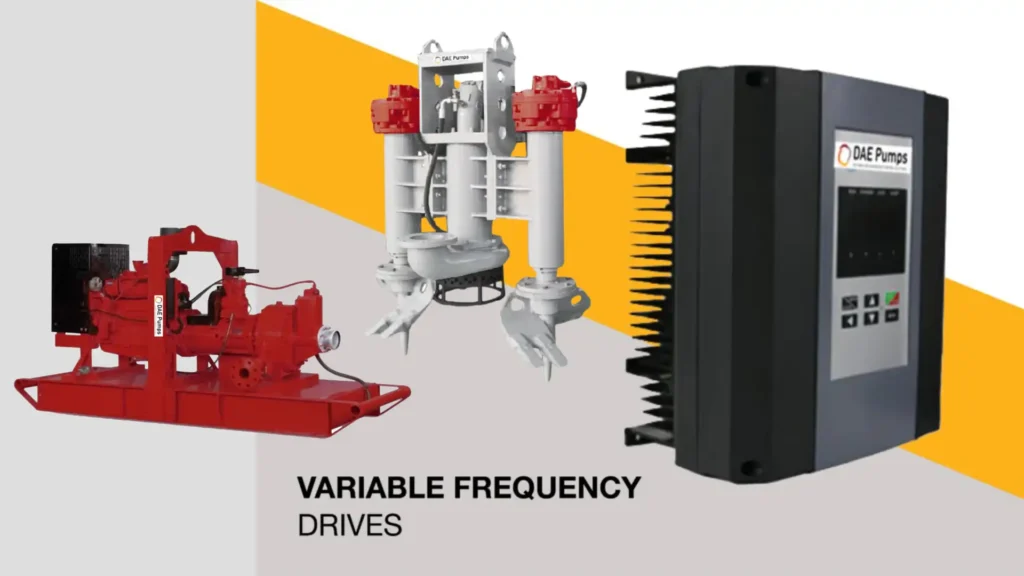

In modern pumping systems, efficiency and control are more important than ever. With rising energy costs and growing demands for reliability, operators seek solutions that enhance pump performance while reducing expenses. One of the most powerful tools for achieving this balance is the Variable Frequency Drive (VFD).

A VFD controls the speed of an electric motor by adjusting the frequency of the electrical power supplied. When applied to pumps, this technology provides unmatched control, flexibility, and efficiency. This article explores how VFDs work, their benefits, and where they are most effectively used.

What is a Variable Frequency Drive (VFD)?

A Variable Frequency Drive is an electronic device that regulates the speed and torque of an electric motor. By varying the input frequency and voltage, it allows the pump to operate at the precise speed needed for a given application.

- Without VFDs: Pumps typically run at constant speed, regardless of demand.

- With VFDs: Pump speed adjusts dynamically to match system requirements, saving energy and reducing wear.

Benefits of Using VFDs in Pumping Systems

Energy Savings

- Pumps without VFDs often waste energy by running at full speed even when demand is low.

- VFDs allow pumps to slow down when full capacity isn’t required, cutting energy consumption significantly.

Extended Equipment Life

- Gradual motor starts reduce mechanical stress on shafts, bearings, and seals.

- Less wear means fewer breakdowns and lower maintenance costs.

Improved Process Control

- Flow and pressure can be fine-tuned for greater precision.

- Especially important in chemical processing, water treatment, and irrigation systems where accuracy matters.

Reduced Water Hammer

- VFDs allow pumps to start and stop smoothly, reducing sudden pressure surges that can damage pipes and valves.

Lower Operational Costs

- Combining energy savings with reduced maintenance translates into significant long-term cost reductions.

Applications of VFDs in Pumping Systems

Municipal Water Supply

Cities and towns use VFDs to match water output with demand, ensuring consistent supply without wasting energy.

Irrigation and Agriculture

Farmers benefit from precise control of water delivery, avoiding over- or under-irrigation and reducing power costs.

HVAC Systems

VFDs in heating, ventilation, and air conditioning systems regulate chilled and hot water circulation, improving efficiency.

Industrial Processes

Industries such as pharmaceuticals, food processing, and chemicals rely on VFDs for accurate dosing and flow control.

Wastewater Treatment

In treatment plants, VFDs manage fluctuating flow conditions and help optimize aeration and pumping operations.

Challenges of Using VFDs

Initial Cost

- VFDs require upfront investment, which may be higher than fixed-speed setups.

- However, energy savings often offset costs over time.

Compatibility Issues

- Not all motors are VFD-compatible; older equipment may need upgrades.

Maintenance and Expertise

- VFDs are electronic devices that require proper installation and occasional servicing.

- Operators must be trained to handle troubleshooting and programming.

How to Decide if a VFD is Right for Your Pumping System

- Evaluate Energy Costs: If pumps run continuously at varying demand levels, VFDs will save significant energy.

- Assess System Needs: If precise flow or pressure control is critical, VFDs provide the accuracy required.

- Consider Equipment Longevity: If mechanical wear is a concern, VFDs can extend pump and motor lifespan.

- Perform a Cost-Benefit Analysis: Weigh initial investment against projected energy and maintenance savings.

Conclusion

Variable Frequency Drives represent a major advancement in pump technology. They deliver energy savings, improved system control, and longer equipment life. While the initial cost may be a consideration, the long-term benefits far outweigh it in most applications.

For organizations and individuals looking to enhance pump efficiency, reduce costs, and improve reliability, investing in VFD technology is a forward-thinking solution.

FAQs

Q1: Do VFDs work with all pumps?

They work with most motor-driven pumps, but older or specialized equipment may need compatibility checks.

Q2: How much energy can a VFD save?

Savings vary, but reductions of 20–50% are common in variable demand systems.

Q3: Can VFDs be installed on existing pumps?

Yes, but motors and control systems must be evaluated for compatibility.

Q4: Do VFDs require regular maintenance?

Minimal maintenance is needed, but periodic inspections of electronics and cooling systems are recommended.

Q5: Are VFDs suitable for residential use?

Yes, especially in large residential irrigation or booster pump systems, though they are more common in commercial and industrial settings.